- First Off: A Summary

- Setting the Baseline: What is Inventory Management?

- 4 Inventory management methods

- Inventory Management Challenges

- Common Inventory Technology Challenges

- Bridging the Divide with Technology

- Inventory Problem Solving in Action

- Step-by-step to an effective inventory system

- How inventory technology can help you

- To wrap it up

An effective inventory management is about maintaining the right balance of stock to meet demand while minimizing costs. Keep reading to learn how it can transform your operations!

Today’s customers have an increasing expectation of an Amazon-level of transparency in all stages of delivery, even in the direct-to-business world. In order to streamline your workflows and create the needed level of transparency across your organization, from back office to the production floor, all the way through shipping, effective inventory management is the key ingredient for success.

Although there isn’t a one-size-fits all approach to managing inventory, our CEO, Scott Love, recently shared some considerations for manufacturers in a recent webinar he presented for Claris, of Claris FileMaker.

First Off: A Summary

Since most of us like a good executive summary, here’s a quick overview of the webinar:

- Considerations when choosing an inventory management system

- Challenges he’s seen manufacturers face with inventory management

- Examples of inventory management in action

Setting the Baseline: What is Inventory Management?

Most people see inventory as a way to track how much stuff you have purchased and how much stuff you have removed or sold from that stock. But as digital transformation takes hold, companies are rethinking what their technology and processes look like. As a result, inventory management becomes more about workflow. Now you have to ask yourself: “What do I want to do with that list?”

Although it’s easy to rebrand inventory as a workflow problem, inventory challenges can run the gamut. Next, let’s explore how those challenges have manifested in the field based on our experience.

4 Inventory management methods

Effective inventory management is all about keeping the right amount of stock on hand to meet customer needs while avoiding waste and extra costs. To help you manage inventory effectively, here are 4 popular methods explained in a simple way.

Just-in-Time (JIT)

The Just-in-Time (JIT) method focuses on inventory control by ordering stock only when it’s needed, which helps reduce storage costs and waste. For example, instead of keeping a large stock, you’d order products just before they’re needed for production or sale. This method works best when you have a reliable supplier and use inventory software to track what’s running low.

Economic order quantity (EOQ)

Economic Order Quantity (EOQ) helps businesses determine the ideal order quantity and adjust inventory levels to minimize total costs, including ordering and holding expenses. This formula-based approach is one of the most widely used inventory management techniques, offering a balance between cost efficiency and stock availability. Incorporating inventory management software can simplify calculations and enhance accuracy.

Day of sales inventory (DSI)

Days of Sales Inventory (DSI) measures how long your stock sits on the shelf before being sold. A lower number means you’re selling quickly, which is great! A higher number might mean you’re ordering too much. Tracking your DSI is one of the simplest tips for effective inventory management and helps you avoid wasting money.

Material requirements planning (MRP)

Material Requirements Planning (MRP) focuses on ensuring the availability of materials for production schedules. It aligns inventory levels with production demand, preventing shortages or delays. MRP is especially useful for manufacturers and relies heavily on inventory software management to forecast demand, track materials, and streamline the production process.

Inventory Management Challenges

Although no two inventory management scenarios are alike, many of them share the following issues.

Complexities in the Supply Chain

Many organizations work with a variety of vendors to get materials or products. There are two ways that this can happen: the easy way or the hard way.

If an organization is just placing an order from a standard vendor, the process is simple. But it’s rarely so straightforward, particularly if you have a more complex product with international parts. Most organizations are trying to draw resources from multiple suppliers, so things like tracking quality, lead time, and customs delays all have to be factored into how the inventory is tracked and delivered to both internal and external customers.

Measuring the Value of Your Inventory

There are different ways of measuring the value of your inventory. If you hold onto inventory for a long period of time, this becomes an important point when measuring the value of your business holdings. If you’re a company that deals with products that are interchangeable, like nails or sewing notions, each individual item is interchangeable with another.

However, if you purchase products at different times, or at different prices, you’ll need to have a way to figure out the cost of inventory after you figure in those differences. Whatever inventory tools you choose must be able to do cost averaging across time, or you’ll need to track by attribute like bin, or price rank—another important characteristic.

Tracks Returns and Shrinkage

When someone mentions “inventory,” they often think of retail. And if you’re dealing with the retail industry, you have customer variables that will need to be tracked. Specifically, returns and theft.

In the case of returns, organizations don’t often have a flexible method of returning inventory to stock outside of the direct-from-vendor relationship.

In the case of theft from a showroom floor, it’s critical that your employees have a simple and efficient way to track shrinkage. Lacking portable, flexible systems leads to inefficient human resource time and results in dirty data.

Common Inventory Technology Challenges

Staying connected to your production environment can be an amazing way to understand what challenges your team is facing on the floor and in the back office. As we’ve immersed ourselves into our clients inventory challenges, here is what pops up most often:

The Dreaded Spreadsheet – If you’ve got piles of spreadsheets managing your critical information, it’s time to consider a unified system that distributes the most up-to-date information to all teams across the whole organization.

Inadequate Inventory Software – Too many organizations purchase expensive inventory or ERP solutions and only use 10% of the features available. Or worse yet, they rely on multiple, disparate homegrown systems made by enterprising employees, trying to create tools to help them do their jobs more efficiently. If this sounds like your organization, it’s time to consider custom software to give you the features you need across your organization.

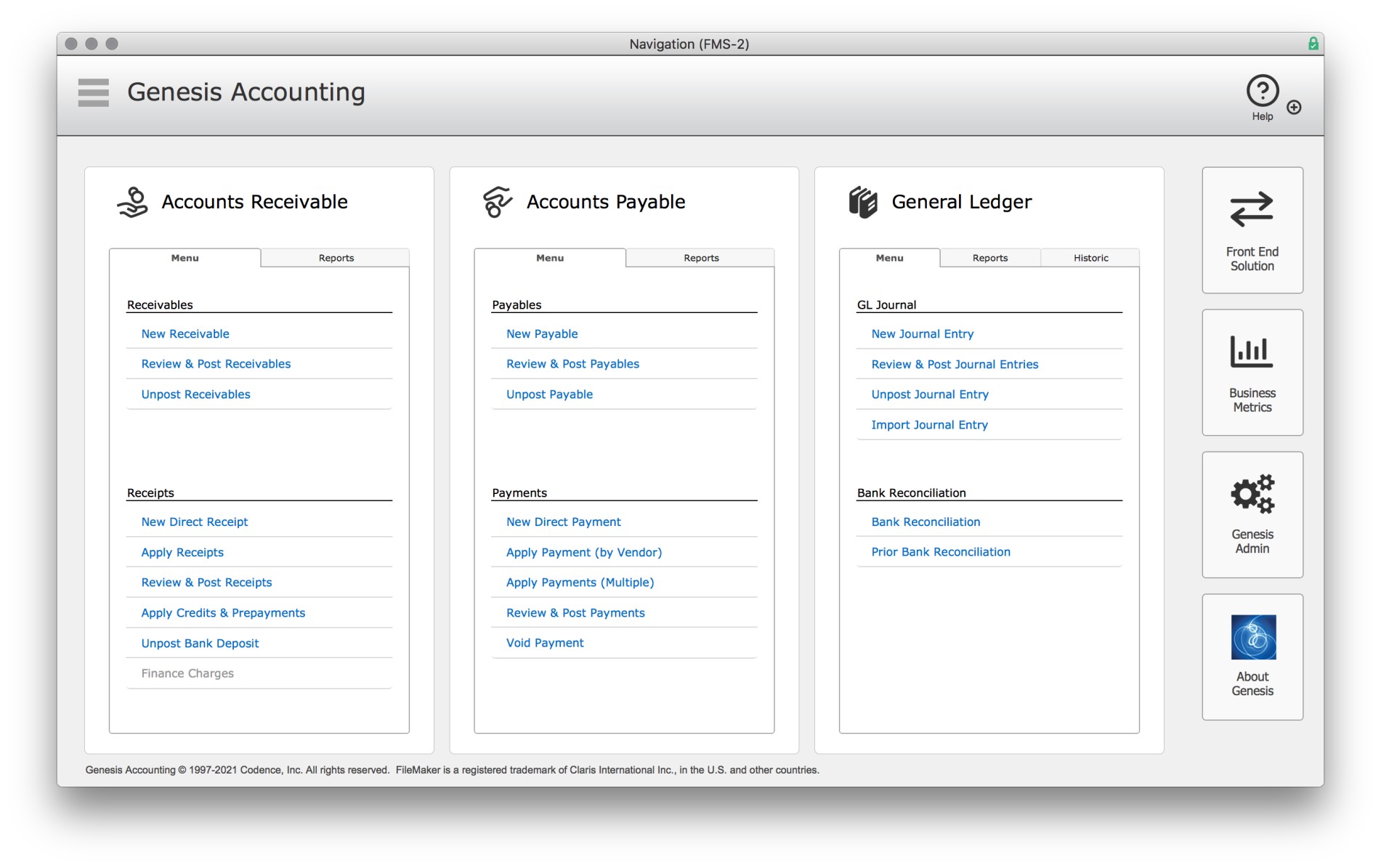

Information Silos – With information needing to be formatted in unique ways across systems, organizations often resort to double entry to make sure it’s done right. We see this often in the case of accounting. Concerned about security and data formatting, organizations feel this is the best approach, but in the end it’s time consuming with the potential for error.

Human Resource Cost – When an organization comes across challenges with their inventory, it can be tempting to make up for inadequate technology with labor. When organizations rely on labor to wrestle with software, or type things manually across multiple systems, they are spending unnecessary monetary resources and drawing people away with repetitive tasks from higher value efforts.

Bridging the Divide with Technology

If you find yourself running into any of these challenges, there is a better way. Once you recognize the gaps in your process, you can apply both the technology and the problem solvers you want to be involved in a solution. For instance, at Codence, we tend to be the problem solvers, working with those who have identified the challenges. Then we use Claris FileMaker to create flexible, custom solutions to streamline your problem-solving process.

Inventory Problem Solving in Action

Here are a few examples using our custom approach to help give a sense for how this could work in the actual business environment.

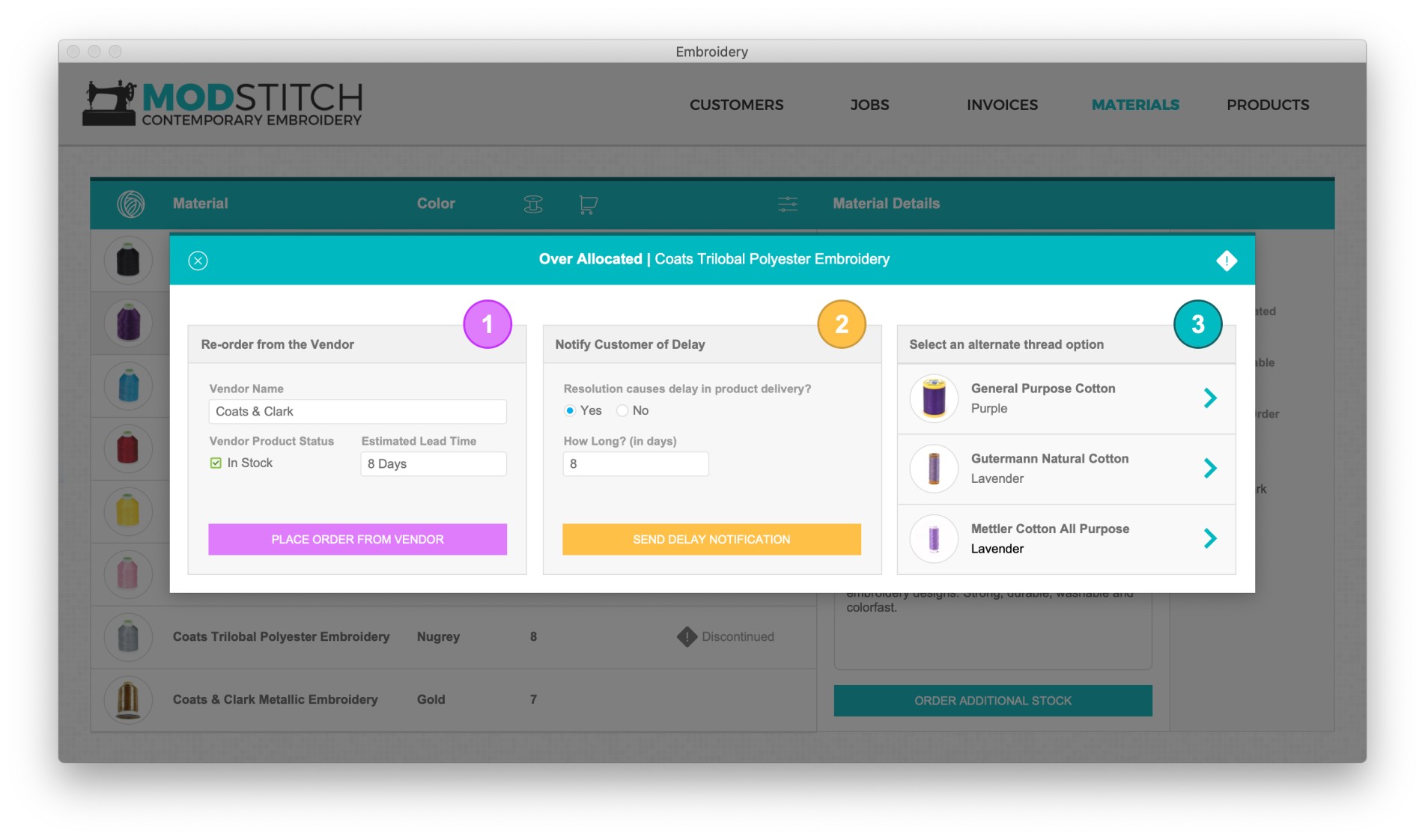

Stitching Efficiency at an Embroidery Company

Company: An embroidery company that embroiders logos, slogans, and images on soft goods including hats, t-shirts, and other wearable items.

Challenge: This embroidery organization uses thread to embroider soft goods. They buy thread in spools, but they consume it in yards. Some letters (like the letter G) consume more thread than others (like the letter S). Soft goods need to be tracked by size, style, and color. Customer goods can’t be added to the main inventory, but still need to be tracked by size, style, and color.

Solution: Codence created three separate, non-interchangeable inventory systems. One more complex system allows operators to calculate thread use, order new spools, and calculate lead time to manage customer expectations. The next system tracks the inventory they are selling to customers to be embroidered, and the final system tracks the customer-provided inventory.

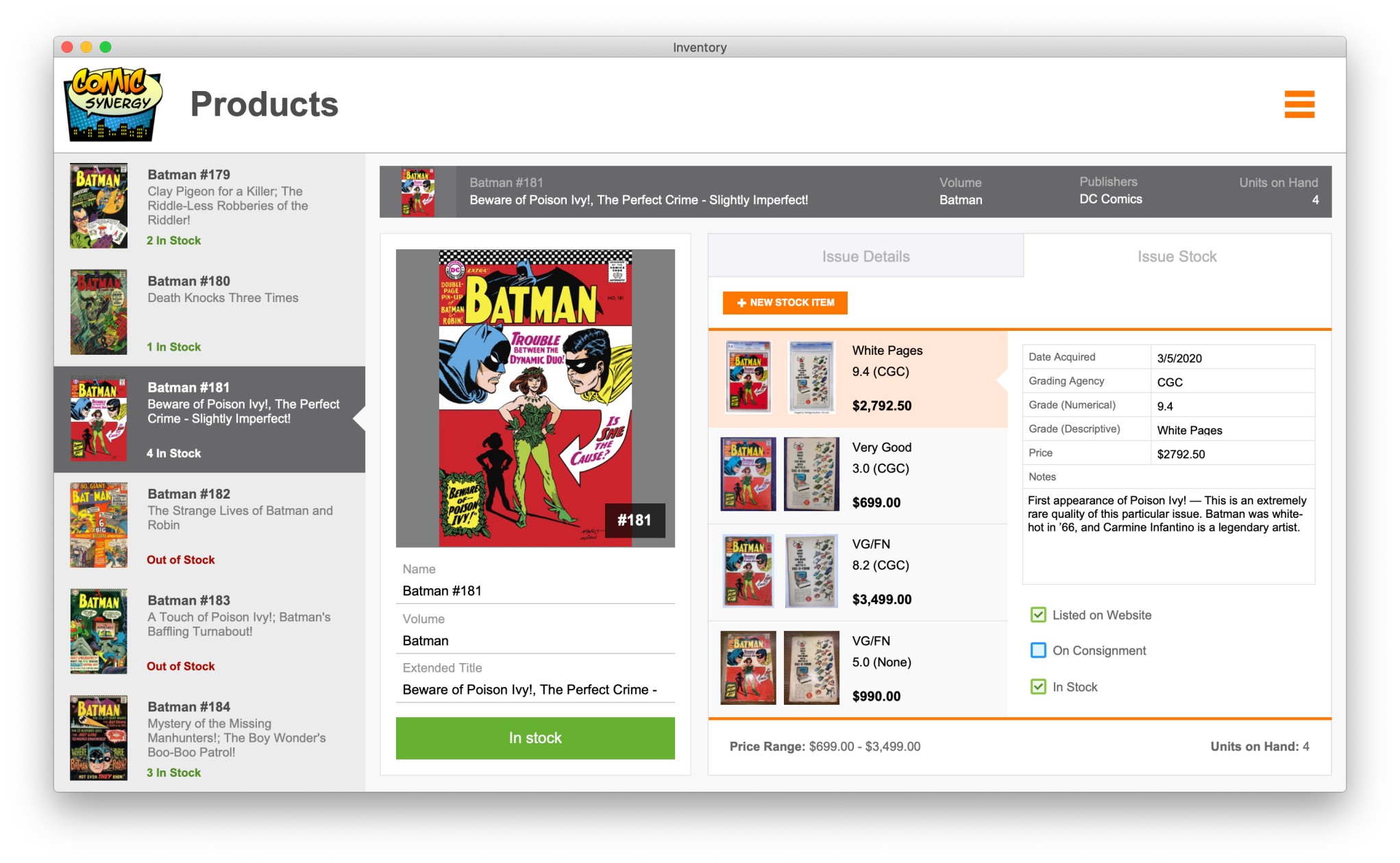

BANG, POW, BOOM: Comic Book Store Inventory Tracking

Company: A comic book shop that sells new and used comic books.

Challenge: Vintage and used comic books are graded by quality. A copy of Batman 181 that is graded at a 9.4 is worth thousands of dollars while one that has been colored during a fit of creativity is not valuable. As a result, each item is a category of one and not interchangeable with other “like” items. The store also sells comics on consignment.

Solution: This organization used a Claris FileMaker inventory app, to start, and then looped Codence in to help build upon and refine the app. The resulting inventory system acted as a way to keep track of their in-house inventory, and their customer inventory. It also served as an alert to the retail associates on Slack when a rare item was added to the inventory that was also on a customer wishlist. Then the associate would use Twilio to text the customer.

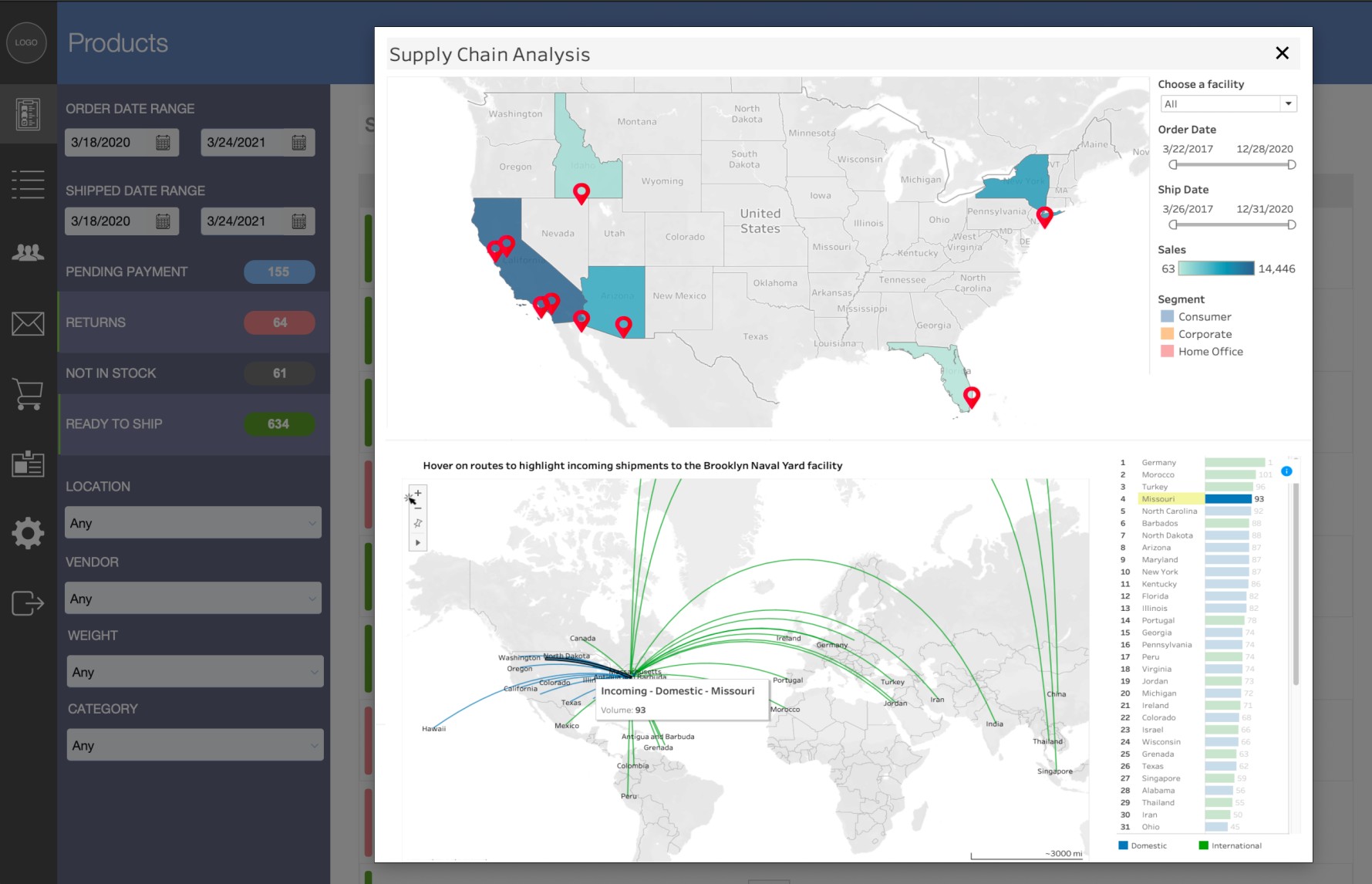

Making the Stuff: Manufacturing Company Inventory

Company: A global manufacturing company that creates widgets that ship all over the world.

Challenge: This organization had facilities all over the country and the responsibility of managing the supply change. As they brought in materials from around the world, they were trying to create efficiencies on where the materials would be delivered, based on the part’s usage. If a part is to be assembled, it goes to California. If it’s going to be sold in New York, it’ll be delivered to storage at the Brooklyn Naval Yard.

Solution: Codence created a visual map that integrated into Tableau. In this case, Claris FileMaker was fueling Tableau visualizations to ensure the right tool was being used for the right job. This offered clarity and transparency into which shipment would go where and helped ensure the company was saving both shipping costs and time.

Step-by-step to an effective inventory system

Creating an effective inventory system might seem overwhelming, but breaking it down into simple steps makes it manageable. Here’s how you can get started and build a system that works for your business.

- Identify your challenges: start by understanding the specific inventory situations affecting your process. Are you struggling with overstock, stockouts, or inaccurate tracking? Pinpointing these problems gives you a clear focus;

- Evaluate the impact: determine how these challenges are affecting your business. Are they causing financial loss, wasting time, or lowering employee morale? Knowing the impact helps you prioritize what to fix first;

- Assemble your team: decide who will be responsible for implementing and maintaining the inventory system. This could include warehouse staff, managers, or even external consultants;

- Create a roadmap: develop a step-by-step plan to address the challenges. Start small and gradually add more complexity as your team becomes comfortable with the system;

- Choose the right technology: implement inventory management software that suits your needs. Look for tools that track stock levels, generate reports, and integrate with other systems for smoother operations;

- Train your team: ensure everyone involved understands how to use the new system. Provide training sessions to reduce errors and build confidence in the process;

- Monitor and adjust: regularly review the system’s performance. Are stock levels more accurate? Are processes faster? Use this data to refine and improve over time.

By following these steps, you’ll create an inventory system that grows with your business, improving efficiency and reducing stress for your team. Remember, building an effective system is a process—take it one step at a time!

How inventory technology can help you

Inventory technology is an essential asset for businesses seeking to streamline their inventory management processes. By offering real-time tracking, it enables accurate monitoring of stock levels, helping companies avoid costly mistakes like overstocking or running out of stock.

One of the key strategies for effective inventory management is leveraging automation. Advanced inventory management software excels at handling repetitive tasks, such as reordering products, generating detailed reports, and tracking shipments, freeing up valuable time and resources for other business priorities.

Technology streamlines inventory management by integrating seamlessly with systems like accounting and e-commerce platforms, ensuring information flows effortlessly across your operations. This level of connectivity simplifies inventory management, empowering you to make data-driven decisions based on detailed analytics and industry trends.

The right inventory management software enhances accuracy and scalability. As your business grows, the technology evolves with you, providing the flexibility and reliability needed to handle more complex operations efficiently.

To wrap it up

Effective inventory management is about more than just tracking stock—it’s about creating a system that ensures you have the right products, in the right quantities, at the right time. By exploring methods like Just-in-Time, EOQ, DSI, and MRP, addressing common challenges, and embracing inventory software management, you can streamline your operations and improve accuracy. With the right approach, your business can achieve improved efficiency and sustainable growth.

Ready to elevate your inventory system? Discover the power of Claris FileMaker and how it can help you create custom solutions tailored to your business needs.

Subscribe to get the latest in your inbox.

Built with you in mind

Speak to one of our expert consultants about making sense of your data today. During

this free consultation, we'll address your questions, learn more about your business, and

make some immediate recommendations.