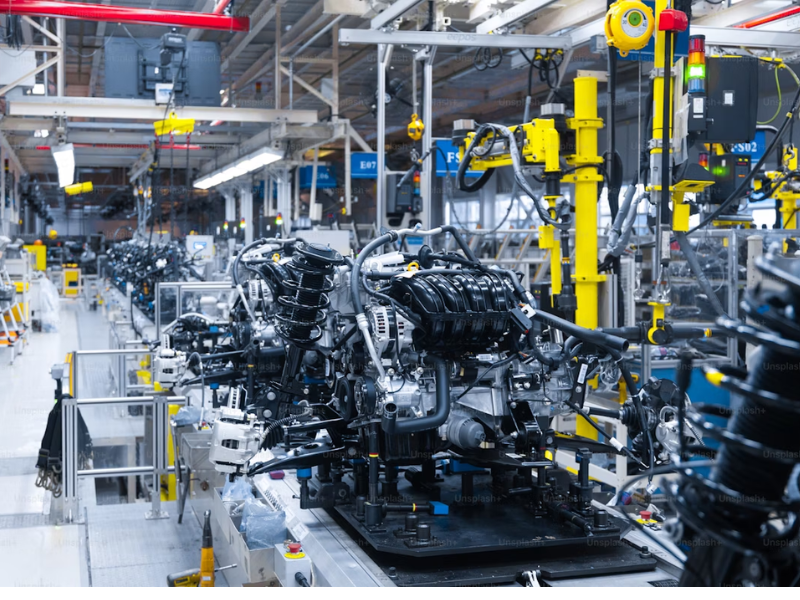

Genesis BI lets manufacturers track performance, monitor production, and spot bottlenecks early to prevent costly issues.

Running a plant efficiently isn’t just about producing faster. It’s about understanding exactly what’s happening at every stage of operations and acting before small issues turn into costly disruptions. Many factories still rely on outdated data, fragmented spreadsheets, and manual reports that don’t reflect the reality on the shop floor.

This post shows how Genesis BI, a custom business intelligence solution, helps production, IT, and operations teams monitor live KPI tracking, optimize workflows, reduce waste, and make faster, more reliable decisions using manufacturing data.

Boosting Manufacturing Performance with KPIs

In today’s manufacturing environment, KPIs are essential for keeping operations efficient and responsive. Unlike traditional reports that appear at the end of the day or week, dashboards provide continuous visibility into production processes.

Immediate access to accurate data allows managers to identify bottlenecks, monitor performance, and make decisions as events happen. Minor issues can be addressed before they escalate into costly disruptions.

KPIs also foster a data-driven culture. Decisions are based on precise, current information, helping teams optimize workflows, align resources with production demands, and increase overall efficiency. Manufacturing automation further reduces manual intervention and supports higher productivity across the plant.

Some of the most valuable KPIs tracked in real time include:

- Production Achievement: Measures how frequently production meets target levels.

- Throughput: Tracks the number of products a machine, line, or plant produces in a given period.

- Inventory Turnover: Reflects how quickly inventory is replenished, indicating resource efficiency.

- Demand Forecasting: Estimates materials needed to meet future customer demand.

- Cycle Time: Average time required to complete the production of an item or component.

- Changeover Time: Time lost when switching tasks, products, or lines, including shift changes.

- Cost Avoidance: Savings from preventive maintenance compared to costs of failures and production loss.

- Cash-to-Cycle Time: Monitors the period between material expenses and revenue generated from sales.

Benefits of monitoring

- Prevent production delays

- Improve response times

- Enable proactive management

- Optimize resource usage

- Reduce waste

- Ensure more efficient and profitable operations

Read more: How Custom FileMaker Apps Optimize Manufacturing Workflows

What Visibility Means for Manufacturing Plants

Currently, only 16 percent of manufacturers have true visibility into their production. Many still rely on delayed or fragmented information, increasing the risk of inaccurate decisions and production bottlenecks.

Dashboards allow continuous monitoring at every stage of the process. Teams can identify bottlenecks, adjust workloads, and detect anomalies before they escalate. This also helps anticipate equipment failures, optimize resources, and improve coordination across departments.

Key advantages:

- Faster, data-driven decisions

- Reduced production interruptions

- Higher product quality and consistency

- Improved operational safety

- Greater efficiency and productivity supported by automation

How Genesis BI Powers KPI Tracking

Genesis BI is a FileMaker for manufacturing solution that centralizes data in a single, actionable dashboard. It transforms complex information into clear insights, helping teams make faster decisions, anticipate issues, and increase overall efficiency.

Core features:

Dynamic Dashboards

Interactive views let managers track KPIs in real time and customize visualizations. For example, a production manager can compare line efficiency and shift performance on a single screen without toggling between spreadsheets or separate manufacturing dashboard software.

Instant Data Updates

Floor-level data updates automatically to ensure accuracy and reliability. If a machine drops in performance, alerts are sent in real time for immediate intervention using production monitoring tools.

Seamless Integrations

Connects easily to ERP, MES, CRM, and other systems, creating a unified data ecosystem. Coordinators can assess stock, production, and sales capacity instantly without manual consolidation.

Powerful Visualization

Complex data is transformed into clear charts and reports accessible to all levels of the operation.

Operators and supervisors can spot bottlenecks, quality deviations, or optimization opportunities without advanced technical training, leveraging manufacturing analytics tools.

Integrating Genesis BI Into Manufacturing Workflows

Genesis BI centralizes information from multiple sources, eliminating redundancy and providing a full view of operational performance. Teams can collaborate efficiently, make quick decisions, and coordinate actions across departments.

For instance, production managers can adjust workloads in real time based on inventory and order data, while maintenance teams receive immediate alerts about equipment issues.

This integration also supports continuous improvement initiatives, helping identify bottlenecks, optimize workflows, and plan resource investments based on accurate data.

By breaking down data silos, Genesis BI dashboards promote greater transparency, efficiency, and agility across the supply chain and shop floor.

Read more: How to Accurately Manage Production Costs in Manufacturing

The Business Impact of KPI Visibility

Visibility with Genesis BI converts data into actionable results. Dashboards and instant alerts allow teams to identify and resolve issues before they escalate, improving quality control and maintaining performance standards.

Well-informed teams can make strategic decisions that enhance competitiveness, efficiency, and overall productivity. For example, a factory using Genesis BI might detect hidden bottlenecks in an assembly line, reduce cycle times, minimize waste, and increase production target compliance.

Key benefits:

- Reduced operational costs

- Faster problem resolution

- Continuous quality improvement

- Increased efficiency and productivity

- Sustainable competitive advantage

Why Choose Codence for Manufacturing Insights

Codence delivers custom solutions that combine FileMaker expertise with practical experience in BI and manufacturing. More than a software provider, Codence acts as a strategic partner, helping plant leaders turn data into fast, reliable decisions.

Decades of custom system development ensure each solution is tailored to operational needs, integrates multiple data sources, and provides insights through manufacturing dashboard software.

As a Claris partner, Codence delivers robust, secure, and scalable platforms with modular development, ongoing support, and flexibility to adapt as your plant grows or faces new demands.

Schedule a consultation with Codence to start transforming your manufacturing operations. Our custom solutions provide insights, streamline workflows, and empower teams to make faster, smarter decisions.

Stay in touch!

Built with you in mind

Speak to one of our expert consultants about making sense of your data today. During

this free consultation, we'll address your questions, learn more about your business, and

make some immediate recommendations.